Production Workshop

TECHNOLOGICAL

PROCESS

PROCESS

Zhongxing Equipment strictly controls every link of the supply chain from ultra-pure steel smelting to finished product inspection and delivery to provide effective guarantee for the quality of products.

-

Workshop

Operation

Staff

Observation

Production

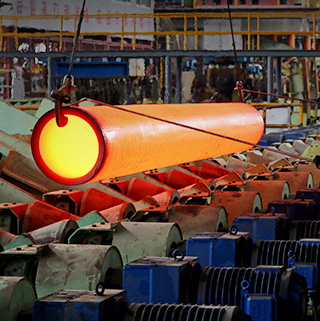

Production of raw material of super-pure steel: We strive to solve the quality problem of billet and reduce the anisotropy of billet, so as to ensure uniform steel composition, low inclusion content, low harmful elements content and uniform structure. At the same time, the quality stability of products is further ensured, so that the performance of each part of the single pipe and the overall performance of the same batch of pipes are greatly enhanced. Besides, the safety factor of the customer's device or equipment is greatly improved, and the service life is extended, which greatly lowers the cost of replacement and maintenance.

Zhongxing Equipment strictly controls every link of the supply chain from ultra-pure steel smelting to finished product inspection and delivery to provide effective guarantee for the quality of products.

-

Guarantee

Workshop

Mechanics

Quality Control

The advantages of the integrated industrial chain ensure that we are different from any other industry peers. Starting from steelmaking and obtaining high quality billet to practically product quality control, Zhongxing Equipment products have been keeping their excellent and stable quality with highly mature production technology, strict and fine nondestructive physicochemical inspection, as well as the compilation of technical documents and supervision in the management process. Over the years, Zhongxing Equipment has continuously met the stringent requirements of customers in different industries for high-end customized products.

Zhongxing Equipment has passed various complete quality system certifications at home and abroad, and it strictly implements all kinds of control and inspection standards from raw materials to final products.

-

Measure

Equipment

Auxiliary

Testing

Nondestructive testing includes hydraulic ultrasonic testing, eddy current testing, magnetic particle testing and penetration testing, which are used for overall testing of pipes to determine whether there are cracks and interlayers on the surface and inside the steel pipes. In visual inspection, endoscope, calipers and other tools are used to inspect invisible defects and determine whether the dimensions meet the standard. Physicochemical testing includes composition test (using spectrometers and carbon-sulfur analyzers), and mechanical properties test (including drawing at room temperature, drawing at high temperature, and flattening, flaring, impact) and metallographic test (optical microscopy, test of grain size, inclusion, ferrite content, etc.), which are destructive tests used for testing the technological performance of products.

Finished product testing is mainly divided into two parts: nondestructive testing and physicochemical testing. A test plan is developed according to product standard and customer requirement.

EQUIPMENT

DISPLAY

DISPLAY

In the smelting section, the following equipment is equipped:

Rough + refining + electroslag remelting equipment

In the stage of steelmaking, the content of harmful elements, gases and inclusions in the billet should be reduced, and the composition and structure should be uniform to get high quality billet.The 6000T forging machine ensures that large steel billets can be forged effectively and core defects are eliminated. 1200 punch machine can produce large diameter seamless pipes with outside diameter of 1,200mm.

In the stage of steelmaking, the content of harmful elements, gases and inclusions in the billet should be reduced, and the composition and structure should be uniform to get high quality billet.The 6000T forging machine ensures that large steel billets can be forged effectively and core defects are eliminated. 1200 punch machine can produce large diameter seamless pipes with outside diameter of 1,200mm.

CONTACT US

E-mail:

xsb@zxnyzb.com

MESSAGE

Copyright © 2022 ZhongXing Energy Equipment Co., Ltd All Rights Reserved 苏ICP备12015458号 SEO